Search for and open Item Sales Price Calculation List.

On the page that comes up choose New to create a new Item Sales Price Calculation.

A page will open where you can register information about the Item Sales Price Calculation.

Fields

General

No.

The number of the Item Calculation, this will be generated based on the number series chosen in the setup, but can be overwritten.

Order Quantity

Choose the order quantity for the Item Calculation. This field is mandatory and must be filled before Item No. because of the impact this number has on machining and setup times.

Item No.

Choose the item number of the item related to the calculation. This field will only accept items with a BOM. When a suitable item no. is entered the Material-table will be filled with values from the items in the BOM. These values can be overwritten.

Item Description

Description of the item, gathered from the Item Card.

Material spec.

Provide information about the material used in the product. The field is an open textbox, allowing you to specify any changes or updates in the material usage.

Project Code

The Project code related to the Item Calculation. This can help with finding other item calculations related to the same projects for comparison.

Calculation Date

The date is automatically set to the date the Item Calculation is created, but can be overwritten.

Calculated by

This field is automatically set to the user creating the Item Calculation, but can be overwritten.

Locked

By activating this field the Item Calculation is locked, and can no longer be edited.

Total Material Cost

The total material cost calculated from the Material-table, but this can be overwritten.

Total Capacity Cost

The total cost of capacity calculated from the Work-table, but this can be overwritten.

Total Additional Cost

The total cost of additional calculated from the Additional-table, but this can be overwritten.

Total Cost

The total cost of material calculated from the Material-table, but can be overwritten.

Calculation Factor

Choose the profit margin (1,2 gives 20% profit).

Sales Price

The sales price, calculated by Tot. Cost * Calc Factor.

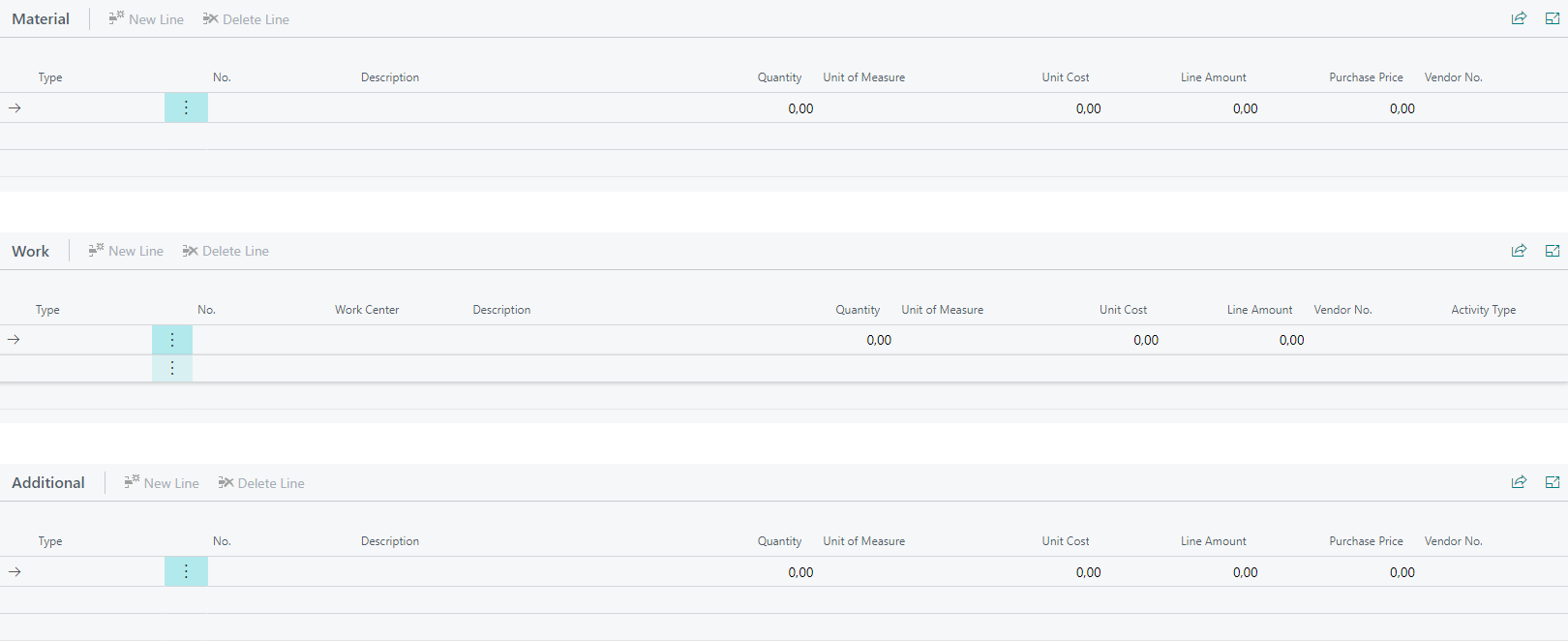

Tables

The tables provide information about the material, work and additional processes that needs to be included in the Item Calculation. All these fields can be overwritten, such that you can change items, prices, quantities, vendors etc as needed.

Material

The Material-table shows information about the items to be included in the calculation, these are automatically gathered from the production BOM of the item, but can be overwritten.

Work

The Work-table shows the route of the item and calculates the working cost.

Additional

The Additional-table is for various costs not included in material or work, this can be shipping or other relevant additional costs for the Item Calculation.

Fields

Type

This field specifies the category related to the cost. The different tables have different types:

-

Material: Item

-

Work: Capacity

-

Additional: Additional

No.

This field specifies the No. of the related category, for example item number in the Material-table.

Description

The Description from the Item Card or Work Center Card.

Quantity

Specifies the quantity item/cost used in the calculation.

Unit of Measure

The unit of the quantity, for example PCS, KG, MIN. The value is gathered from the Item Card or Work Center Card.

Unit Cost

The cost of one unit gathered from the value specified in the Item Card or Work Center Card. This value can be overwritten if there is an update on price, a new vendor or other reasons for price changes.

Line Amount

The field returns the cost of the line, calculated by Quantity * Unit Cost.

Vendor No.

The field is a dropdown menu of all the vendors, it will automatically fill wil the value from the Item Card. This can be changed if you are using a different vendor than the one specified in the Item Card.

Capacity Type

Specifies the category of the line. The categories are as follows:

-

Work Center

-

Machine Center

Capacity Center

Specifies which capacity center the line belongs to. Type Work Center gives choices from the Work Centers-list while Machine Center gives choices from the Machine Centers-list.

Activity type

Specify what activity is related to the line. For example, machining, coating and assembly.